.jpg)

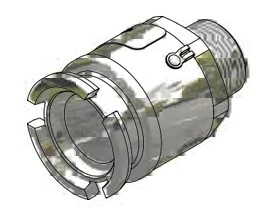

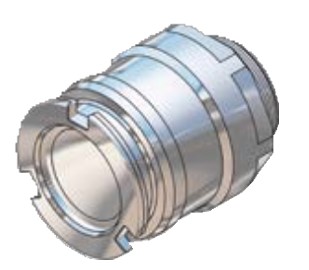

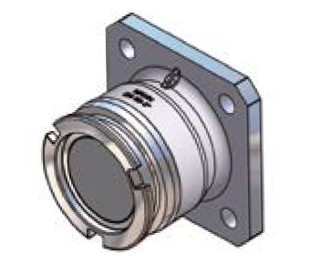

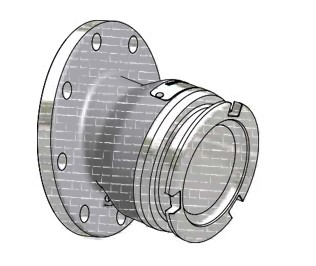

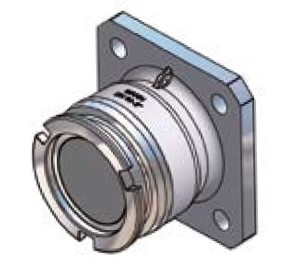

Droogontkoppelbare koppelingen

Tankeenheid (adapter) en slangeenheid (koppeling)

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Brass / Gunmetal |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Stainless Steel |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Titan |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Hastelloy |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

PEEK |

6 bar / 87 psi |

9 bar / 131 psi |

30 bar / 435 psi |

Aansluitingen

¾", 1" en 1¼" met BSP-, NPT- of metrische schroefdraad, of flensinlaat.

Toepassingen

Voor industriële procesinstallaties, tankwagens en -wagons, IBC-containers, de farmaceutische en petrochemische industrie, het tanken van diesellocomotieven, enz. Aanbevolen voor alle soorten overslag van kleine bulkvloeistoffen, inclusief het vullen van containers en vaten, of voor elke toepassing waarbij morsen tot een minimum moet worden beperkt.

Media

Aardolieproducten: benzine, diesel, olie, enz.

Chemische producten: bijv. ethyleenoxide, propyleenoxide, acrylonitril, butadieen, ammoniak, vinylchloride, tolueen, xyleen, zwavelzuur, fenol, enz.

Gas: dampterugwinnings-/balanssystemen voor diverse media.

Materiaal behuizing

Aluminium, messing, roestvrij staal, Hastelloy en PEEK. Overige op aanvraag.

Afdichtingen

Standaardafdichtingen in FPM (Viton®) - alternatief EPDM, FKM (Chemraz®, Kalrez®), NBR/HBNR. Andere materialen op aanvraag.

Hoge stroomsnelheden / lage drukval

Maakt maximale productoverdracht mogelijk met minimale verliezen.

Aanbevolen maximale stroomsnelheden

200 liter/minuut (brandstof).

Selectiviteit

- vermijd productvermenging

Om productverontreiniging door het aansluiten van een slangunit op de verkeerde tankunit te voorkomen, zijn er verschillende uitvoeringen van de slang- en tankunits beschikbaar. Elke unit heeft een aantal selectieve posities, aangegeven met een gecodeerd onderdeelnummer volgens de koppelingsmaat; geef dit aan bij het plaatsen van de bestelling. Zie pagina 32 en verder.

Uitwisselbaarheid

Compatibel met koppelingen van andere fabrikanten.

Slangunit met geïntegreerde wartel

Alle slangunits worden geleverd met een geïntegreerde wartel.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Flat Seal |

kg |

lbs |

|||

|

F ½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

0,3 |

0.7 |

T1133A1101B |

|

F ¾" BSP |

T101A1101B |

|||||

|

F 1" BSP |

T103A1101B |

|||||

|

F 1¼" BSP |

T105A1101B |

|||||

|

F M 54 x 1,5 |

T1138A1101B |

|||||

|

F ½" NPT |

— |

T1132A1101 |

||||

|

F ¾" NPT |

T102A1101 |

|||||

|

F 1" NPT |

T104A1101 |

|||||

|

F 1¼" NPT |

T106A1101 |

|||||

|

F ½" BSP |

Br |

PUR (Polyurethane) |

0,7 |

1.5 |

T1133A2201B |

|

|

F ¾" BSP |

T101A2201B |

|||||

|

F 1" BSP |

T103A2201B |

|||||

|

F 1¼" BSP |

T105A2201B |

|||||

|

F M 54 x 1,5 |

T1138A2201B |

|||||

|

F ½" NPT |

— |

T1132A2201 |

||||

|

F ¾" NPT |

T102A2201 |

|||||

|

F 1" NPT |

T104A2201 |

|||||

|

F 1¼" NPT |

T106A2201 |

|||||

|

F ½" BSP |

SS |

PTFE (Teflon®) |

0,7 |

1.5 |

T1133A4401B |

|

|

F ¾" BSP |

T101A4401A |

|||||

|

F 1" BSP |

T103A4401A |

|||||

|

F 1¼" BSP |

T105A4401A |

|||||

|

F M 54 x 1,5 |

T1138A4401A |

|||||

|

F ½" NPT |

— |

T1132A4401 |

||||

|

F ¾" NPT |

T102A4401 |

|||||

|

F 1" NPT |

T104A4401 |

|||||

|

F 1¼" NPT |

T106A4401 |

|||||

|

F ¾" BSP |

Titan |

PTFE (Teflon®) |

0,4 |

0.9 |

T101A6601A |

|

|

F 1" BSP |

T103A6601A |

|||||

|

F 1¼" BSP |

T105A6601A |

|||||

|

F ¾" NPT |

— |

T102A6601 |

||||

|

F 1" NPT |

T104A6601 |

|||||

|

F 1¼" NPT |

T106A6601 |

|||||

|

F ¾" BSP |

Hastelloy |

PTFE (Teflon®) |

0,8 |

1.8 |

T101A7701A |

|

|

F 1" BSP |

T103A7701A |

|||||

|

F 1¼" BSP |

T105A7701A |

|||||

|

F ¾" NPT |

— |

T102A7701 |

||||

|

F 1" NPT |

T104A7701 |

|||||

|

F 1¼" NPT |

T106A7701 |

|||||

|

F ¾" BSP |

PEEK |

PTFE (Teflon®) |

0,1 |

0.2 |

T101A9901A |

|

|

F 1" BSP |

T103A9901A |

|||||

|

F 1¼" BSP |

T105A9901A |

|||||

|

F ¾" NPT |

— |

T102A9901 |

||||

|

F 1" NPT |

T104A9901 |

|||||

|

F 1¼" NPT |

T106A9901 |

|||||

1) F = Binnendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Materiaal: Al = Aluminium, Br = Messing, SS = Roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijvoorbeeld EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® en Teflon® zijn geregistreerde handelsmerken van DuPont, DuPont Elastomers.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

M ¾" BSP |

|

|

|

|

T169A1101 |

|

|

M ¾" NPT |

Al |

|

T170A1101 |

|||

|

M 1" BSP |

T171A1101 |

|||||

|

M 1" NPT |

|

Standard: |

T172A1101 |

|||

|

M ¾" BSP |

|

|

|

T169A1101 |

||

|

|

FPM/FKM |

|||||

|

M ¾" NPT |

T170A1101 |

|||||

|

Br |

(Viton®)

Other on |

|||||

|

M 1" BSP |

T171A1101 |

|||||

|

M 1" NPT |

T172A1101 |

|||||

|

|

request. |

|||||

|

M ¾" BSP |

|

|

|

T169A4401 |

||

|

M ¾" NPT |

SS |

|

T170A4401 |

|||

|

M 1" BSP |

T171A4401 |

|||||

|

M 1" NPT |

|

|

T172A4401 |

|||

1) M = Buitendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Materiaal: Al = Aluminium, Br = Messing, SS = Roestvrij staal,

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijvoorbeeld EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

undrilled |

|

|

|

|

T118A1101 |

|

|

DN 25 PN 10 / 16 Type A |

|

|

|

|

T123A1101 |

|

|

DN 25 PN 25 / 40 Type A |

Al |

|

1,1 |

2.4 |

T124A1101 |

|

|

1" ASA 150 |

|

|

|

|

T151A1101 |

|

|

1" ASA 300 |

|

|

|

|

T152A1101 |

|

|

undrilled |

|

|

|

T118A2201 |

||

|

DN 25 PN 10 / 16 Type B |

|

|

|

|

T123A2201 |

|

|

DN 25 PN 25 / 40 Type B |

Br |

|

1,6 |

3.5 |

T124A2201 |

|

|

1" ASA 150 |

|

|

|

|

T151A2201 |

|

|

1" ASA 300 |

|

|

|

|

T152A2201 |

|

|

undrilled |

|

1,5 |

3.3 |

T118A4401 |

||

|

DN 25 PN 10 / 16 Type B |

|

|

T123A4401 |

|||

|

DN 25 PN 25 / 40 Type B |

SS |

Standard: |

T124A4401 |

|||

|

|

FPM/FKM |

|||||

|

1" ASA 150 |

T151A4401 |

|||||

|

|

(Viton®) |

|||||

|

1" ASA 300 |

T152A4401 |

|||||

|

undrilled |

|

Other on |

|

|

T118A6601 |

|

|

DN 25 PN 10 / 16 Type B |

T123A6601 |

|||||

|

|

request. |

|

|

|||

|

DN 25 PN 25 / 40 Type B |

Titan |

|

0,8 |

1.8 |

T124A6601 |

|

|

1" ASA 150 |

|

|

|

|

T151A6601 |

|

|

1" ASA 300 |

|

|

|

|

T152A6601 |

|

|

DN 25 PN 10 / 16 Type B |

|

|

|

T123A7701 |

||

|

DN 25 PN 25 / 40 Type B |

Hastelloy |

|

1,7 |

3.8 |

T124A7701 |

|

|

1" ASA 150 |

T151A7701 |

|||||

|

1" ASA 300 |

|

|

|

|

T152A7701 |

|

|

undrilled |

|

|

|

T118A9901 |

||

|

DN 25 PN 10 / 16 Type B |

|

|

|

|

T123A9901 |

|

|

DN 25 PN 25 / 40 Type B |

PEEK |

|

0,2 |

0.4 |

T124A9901 |

|

|

1" ASA 150 |

|

|

|

|

T151A9901 |

|

|

1" ASA 300 |

|

|

|

|

T152A9901 |

|

1) PN 10 / 16 / 25 / 40 = EN 1092 (types zie pagina 44), ANSI B16.5.

2) Materiaal: Al = aluminium, Br = messing, SS = roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijvoorbeeld EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® is een geregistreerd handelsmerk van DuPont, DuPont Elastomers.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F ½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

0,5 |

1.1 |

S1133A1101B |

|

F ¾" BSP |

S101A1101B |

|||||

|

F 1" BSP |

S103A1101B |

|||||

|

F 1¼" BSP |

S105A1101B |

|||||

|

F M 54 x 1,5 |

S1138A1101B |

|||||

|

F ½" NPT |

— |

S1132A1101 |

||||

|

F ¾" NPT |

S102A1101 |

|||||

|

F 1" NPT |

S104A1101 |

|||||

|

F 1¼" NPT |

S106A1101 |

|||||

|

F ½" BSP |

Br |

PUR (Polyurethane) |

1,4 |

3.1 |

S1133A2201B |

|

|

F ¾" BSP |

S101A2201B |

|||||

|

F 1" BSP |

S103A2201B |

|||||

|

F 1¼" BSP |

S105A2201B |

|||||

|

F M 54 x 1,5 |

S1138A2201B |

|||||

|

F ½" NPT |

— |

S1132A2201 |

||||

|

F ¾" NPT |

S102A2201 |

|||||

|

F 1" NPT |

S104A2201 |

|||||

|

F 1¼" NPT |

S106A2201 |

|||||

|

F ½" BSP |

SS |

PTFE (Teflon®) |

1,3 |

2.9 |

S1133A4401A |

|

|

F ¾" BSP |

S101A4401A |

|||||

|

F 1" BSP |

S103A4401A |

|||||

|

F 1¼" BSP |

S105A4401A |

|||||

|

F M 54 x 1,5 |

S1138A4401A |

|||||

|

F ½" NPT |

— |

S1132A4401 |

||||

|

F ¾" NPT |

S102A4401 |

|||||

|

F 1" NPT |

S104A4401 |

|||||

|

F 1¼" NPT |

S106A4401 |

|||||

|

F ¾" BSP |

Titan |

PTFE (Teflon®) |

0,7 |

1.5 |

S101A6601A |

|

|

F 1" BSP |

S103A6601A |

|||||

|

F 1¼" BSP |

S105A6601A |

|||||

|

F ¾" NPT |

— |

S102A6601 |

||||

|

F 1" NPT |

S104A6601 |

|||||

|

F 1¼" NPT |

S106A6601 |

|||||

|

F ¾" BSP |

Hastelloy |

PTFE (Teflon®) |

1,5 |

3.3 |

S101A7701A |

|

|

F 1" BSP |

S103A7701A |

|||||

|

F 1¼" BSP |

S105A7701A |

|||||

|

F ¾" NPT |

— |

S102A7701 |

||||

|

F 1" NPT |

S104A7701 |

|||||

|

F 1¼" NPT |

S106A7701 |

|||||

|

F ¾" BSP |

PEEK |

PTFE (Teflon®) |

0,3 |

0.7 |

S101A9901A |

|

|

F 1" BSP |

S103A9901A |

|||||

|

F 1¼" BSP |

S105A9901A |

|||||

|

F ¾" NPT |

— |

S102A9901 |

||||

|

F 1" NPT |

S104A9901 |

|||||

|

F 1¼" NPT |

S106A9901 |

|||||

1) F = Binnendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Materiaal: Al = Aluminium, Br = Messing, SS = Roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijvoorbeeld EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® en Teflon® zijn geregistreerde handelsmerken van DuPont, DuPont Elastomers.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

M ¾" BSP |

|

|

|

|

S169A1101 |

|

|

M ¾" NPT |

Al |

|

S170A1101 |

|||

|

M 1" BSP |

S171A1101 |

|||||

|

M 1" NPT |

|

Standard: |

S172A1101 |

|||

|

M ¾" BSP |

|

|

|

S169A1101 |

||

|

|

FPM/FKM |

|||||

|

M ¾" NPT |

S170A1101 |

|||||

|

Br |

(Viton®)

Other on |

|||||

|

M 1" BSP |

S171A1101 |

|||||

|

M 1" NPT |

S172A1101 |

|||||

|

|

request. |

|||||

|

M ¾" BSP |

|

|

|

S169A4401 |

||

|

M ¾" NPT |

SS |

|

|

|

S170A4401 |

|

|

M 1" BSP |

|

|

S171A4401 |

|||

|

M 1" NPT |

|

|

1,4 |

3.0 |

S172A4401 |

|

1) M = Male thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials,

e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

1,1 |

2.4 |

S118A1101 |

|

DN 25 PN 10 / 16 Type A |

S123A1101 |

||||

|

DN 25 PN 25 / 40 Type A |

S124A1101 |

||||

|

¾" ASA 150 |

S149A1101 |

||||

|

1" ASA 150 |

S151A1101 |

||||

|

1" ASA 300 |

S152A1101 |

||||

|

DN 25 DIN 11864 |

S1151A1101 |

||||

|

undrilled |

Br |

1,6 |

3.5 |

S118A2201 |

|

|

DN 25 PN 10 / 16 Type B |

S123A2201 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A2201 |

||||

|

¾" ASA 150 |

S149A2201 |

||||

|

1" ASA 150 |

S151A2201 |

||||

|

1" ASA 300 |

S152A2201 |

||||

|

undrilled |

SS |

2,2 |

4.9 |

S118A4401 |

|

|

DN 25 PN 10 / 16 Type B |

S123A4401 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A4401 |

||||

|

¾" ASA 150 |

S149A4401 |

||||

|

1" ASA 150 |

S151A4401 |

||||

|

1" ASA 300 |

S152A4401 |

||||

|

undrilled |

Titan |

1,2 |

2.7 |

S118A6601 |

|

|

DN 25 PN 10 / 16 Type B |

S123A6601 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A6601 |

||||

|

1" ASA 150 |

S151A6601 |

||||

|

1" ASA 300 |

S152A6601 |

||||

|

DN 25 PN 10 / 16 Type B |

Hastelloy |

2,5 |

5.5 |

S123A7701 |

|

|

DN 25 PN 25 / 40 Type B |

S124A7701 |

||||

|

1" ASA 150 |

S151A7701 |

||||

|

1" ASA 300 |

S152A7701 |

||||

|

undrilled |

PEEK |

0,5 |

1.1 |

S118A9901 |

|

|

DN 25 PN 10 / 16 Type B |

S123A9901 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A9901 |

||||

|

1" ASA 150 |

S151A9901 |

||||

|

1" ASA 300 |

S152A9901 |

||||

1) PN 10 / 16 / 25 / 40 = EN 1092

ASA = ANSI B16.5 (150 o. 300 psi), 150

of 300 psi.

DIN 11864 = DIN 11864-2 (aseptische flens)

2) Materiaal: Al = aluminium,

Br = messing, SS = roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijvoorbeeld EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® is een geregistreerd handelsmerk van DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Brass / Gunmetal |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Stainless Steel |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Titan |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Hastelloy |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

PEEK |

6 bar / 87 psi |

9 bar / 131 psi |

30 bar / 435 psi |

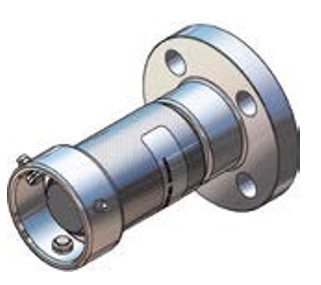

Aansluitingen

1½" en 2" met BSP-, NPT- of S60x6-schroefdraad, of flensaansluiting.

Toepassingen

Voor industriële procesinstallaties, tankwagens en -wagons, ISO-tankcontainers, IBC-containers, farmaceutische en petrochemische industrieën of voor elke toepassing waar morsen tot een minimum moet worden beperkt.

Media

Aardolieproducten: benzine, diesel, olie, enz. Chemische producten: AdBlue, ethyleenoxide, propyleenoxide, acrylonitril, butadieen, ammoniak, vinylchloride, tolueen, xyleen, zwavelzuur, fenol, enz.

Gas: dampterugwinnings-/balanssystemen voor diverse media.

Droog poeder.

Materiaal behuizing

Aluminium, messing/brons, roestvrij staal, Hastelloy en PEEK. Andere materialen op aanvraag.

Afdichtingen

Standaard afdichtingen in FPM (Viton®) - alternatief EPDM, FKM (Chemraz®, Kalrez®), NBR/HBNR. Andere materialen op aanvraag.

Hoge stroomsnelheden / lage drukval

Maakt maximale productoverdracht mogelijk met minimale verliezen.

Aanbevolen maximale stroomsnelheden

900 liter/minuut (brandstof)

Selectiviteit

- vermijd productvermenging

Om productverontreiniging door het aansluiten van een slangunit op de verkeerde tankunit te voorkomen, zijn er verschillende uitvoeringen van de slang- en tankunits beschikbaar. Elke unit heeft een aantal selectieve posities, aangegeven met een gecodeerd onderdeelnummer volgens de koppelingsmaat - specificeer bij het plaatsen van de bestelling. Zie pagina 32 en verder.

Uitwisselbaarheid

Compatibel met koppelingen van andere fabrikanten.

Slangunit met geïntegreerde wartel

Alle slangunits worden geleverd met een geïntegreerde wartel.

Volgens NAVO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 1½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

0,4 |

0.8 |

T207A1101B |

|

F 2" BSP |

T210A1101B |

|||||

|

F S60x6 |

T2108A1101B |

|||||

|

F W2" - 7 |

T2112A1101B |

|||||

|

F 1½" NPT |

— |

0.4 |

0.8 |

T208A1101 |

||

|

F 2" NPT |

T211A1101 |

|||||

|

F 1½" BSP |

Br |

PUR (Polyurethane) |

1,2 |

2.7 |

T207A2201B |

|

|

F 2" BSP |

1,1 |

2.4 |

T210A2201B |

|||

|

F S 60 x 6 |

1,0 |

2.2 |

T2108A2201B |

|||

|

F W2" - 7 |

1,0 |

0.9 |

T2112A2201B |

|||

|

F 1½" NPT |

— |

0,4 |

0.9 |

T208A2201 |

||

|

F 2" NPT |

1,1 |

2.4 |

T211A2201 |

|||

|

F 1½" BSP |

SS |

PTFE (Teflon®) |

1,1 |

2.4 |

T207A4401A |

|

|

F 2" BSP |

1,0 |

2.2 |

T210A4401A |

|||

|

F S60 x 6 |

1,0 |

2.2 |

T2108A4401A |

|||

|

F 1½" NPT |

— |

1,2 |

2.7 |

T208A4401 |

||

|

F 2" NPT |

1,1 |

2.4 |

T211A4401 |

|||

|

F 1½" BSP |

Titan |

PTFE (Teflon®) |

|

|

T207A6601A |

|

|

F 2" BSP |

0,6 |

1.3 |

T210A6601A |

|||

|

F 1½" NPT |

— |

|

|

T208A6601 |

||

|

F 2" NPT |

0,6 |

1.3 |

T211A6601 |

|||

|

F 1½" BSP |

Hastelloy |

PTFE (Teflon®) |

|

|

T207A7701A |

|

|

F 2" BSP |

|

|

T210A7701A |

|||

|

F 1½" NPT |

— |

|

|

T208A7701 |

||

|

F 2" NPT |

|

|

T211A7701 |

|||

|

F 1½" BSP |

PEEK |

PTFE (Teflon®) |

|

|

T207A9901A |

|

|

F 2" BSP |

0,3 |

0.6 |

T210A9901A |

|||

|

F 1½" NPT |

— |

|

|

T208A9901 |

||

|

F 2" NPT |

0,3 |

0.6 |

T211A9901 |

|||

1) F = Binnendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1, S60 x 6 = schroefdraad voor IBC, W 2" stookolieaansluiting Zweden

2) Materiaal: Al = Aluminium, Br = Messing, SS = Roestvrij staal

3) Standaardafdichting FPM/FKM. Alternatieve materialen, bijv. EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

M 2" BSP |

|

|

1,0 |

2.2 |

T278A1101 |

|

|

M 2" NPT |

Al |

Standard: |

|

|

T279A1101 |

|

|

M W2" - 7 |

|

|

T2123A1101 |

|||

|

|

FPM/FKM |

|||||

|

M 2" BSP |

|

|

|

T278A2201 |

||

|

Br |

(Viton®) |

|||||

|

M 2" NPT |

|

|

T279A2201 |

|||

|

M W2" - 7 |

|

Other on |

|

|

T2123A2201 |

|

|

|

request. |

|||||

|

M 2" BSP |

SS |

1,0 |

2.2 |

T278A4401 |

||

|

M 2" NPT |

|

1,1 |

2.4 |

T279A4401 |

||

1) M = Buitendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1, S 60 x 6 = schroefdraad voor IBC, W 2" stookolieaansluiting Zweden

2) Materiaal: Al = Aluminium, Br = Messing, SS = Roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijv. EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® is een geregistreerd handelsmerk van DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 165 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

1,0 |

2.2 |

T219B1101 |

|

DN 40 PN 10 / 16 Type A |

0,9 |

2.0 |

T227B1101 |

||

|

1½" ASA 150 |

0,8 |

1.8 |

T255B1101 |

||

|

DN 50 PN 10 / 16 Type A |

1,0 |

2.2 |

T230B1101 |

||

|

2" ASA 150 |

0,9 |

2.0 |

T257B1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

0,9 |

2.0 |

T265B1101 |

||

|

undrilled Ø 165 mm |

GM |

3,3 |

7.3 |

T219B2201 |

|

|

DN 40 PN 10 / 16 Type B |

2,5 |

5.5 |

T227B2201 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

T228B2201 |

||

|

1½" ASA 150 |

2,2 |

4.9 |

T255B2201 |

||

|

1½" ASA 300 |

|

|

T256B2201 |

||

|

DN 50 PN 10 / 16 Type B |

3,1 |

6.8 |

T230B2201 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

T231B2201 |

||

|

2" ASA 150 |

2,5 |

5.1 |

T257B2201 |

||

|

2" ASA 300 |

|

|

T258B2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

2,4 |

5.3 |

T265B2201 |

||

|

undrilled Ø 165 mm |

SS |

3,2 |

7.1 |

T219B4401 |

|

|

undrilled Ø 165 mm **) |

|

|

T219B4401F |

||

|

DN 40 PN 10 / 16 Type B |

2,4 |

5.3 |

T227B4401 |

||

|

DN 40 PN 10 / 16 Type B **) |

|

|

T227B4401F |

||

|

DN 40 PN 25 / 40 Type B |

2,4 |

5.3 |

T228B4401 |

||

|

DN 40 PN 25 / 40 Type B **) |

|

|

T228B4401F |

||

|

1½" ASA 150 |

1,7 |

3.8 |

T255B4401 |

||

|

1½" ASA 150 **) |

|

|

T255B4401F |

||

|

1½" ASA 300 |

2,1 |

4.6 |

T256B4401 |

||

|

1½" ASA 300 **) |

|

|

T256B4401F |

||

|

DN 50 PN 25 / 40 Type E *) |

2,9 |

6.4 |

T229B4401 |

||

|

DN 50 PN 10 / 16 Type B ) |

2,7 |

6.0 |

T230B4401 |

||

|

DN 50 PN 10 / 16 Type B ** |

|

|

T230B4401F |

||

|

DN 50 PN 25 / 40 Type B |

3,0 |

6.6 |

T231B4401 |

||

|

DN 50 PN 25 / 40 Type B **) |

|

|

T231B4401F |

||

|

2" ASA 150 |

2,4 |

5.3 |

T257B4401 |

||

|

2" ASA 150 **) |

|

|

T257B4401F |

||

|

2" ASA 300 |

2,5 |

5.5 |

T258B4401 |

||

|

2" ASA 300 **) |

|

|

T258B4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

T265B4401 |

||

|

DN 50 DIN 11864 |

|

|

T2152B4401 |

||

|

undrilled Ø 165 mm |

Titan |

|

|

T219A6601 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

T227A6601 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

T228A6601 |

||

|

1½" ASA 150 |

1,7 |

3.8 |

T255A6601 |

||

|

1½" ASA 300 |

|

|

T256A6601 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

T230A6601 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

T231A6601 |

||

|

2" ASA 150 |

|

|

T257A6601 |

||

|

2" ASA 300 |

|

|

T258A6601 |

||

|

undrilled Ø 165 mm |

Hastelloy |

|

|

T219A7701 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

T227A7701 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

T228A7701 |

||

|

1½" ASA 150 |

|

|

T255A7701 |

||

|

1½" ASA 300 B |

|

|

T256A7701 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

T230A7701 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

T231A7701 |

||

|

2" ASA 150 |

|

|

T257A7701 |

||

|

2" ASA 300 |

|

|

T258A7701 |

||

|

undrilled Ø 165 mm |

PEEK |

|

|

T219A9901 |

|

|

DN 40 PN 10 / 16 Type B |

1,0 |

2.0 |

T227A9901 |

||

|

1½" ASA 150 |

|

|

T255A9901 |

||

|

DN 50 PN 10 / 16 Type B |

1,0 |

2.0 |

T230A9901 |

||

|

2" ASA 150 |

1,0 |

2.0 |

T257A9901 |

||

*) Type E (met spie), EN 1092-1, zie p. 44

**) Flens met standaarddikte

1) PN 10 / 16 / 25 / 40 = EN 1092

(typen zie pagina 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = oude standaard TW, 10 bar. DIN 11864 = DIN 11864-2 (aseptische flens)

2) Materiaal: Al = aluminium,

GM = brons, SS = roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijv. EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® is een geregistreerd handelsmerk van DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 1½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

1,2 |

2.7 |

S207A1101B |

|

F 1½" BSP-B Mouth*) |

|

|

S207A1101BI |

|||

|

F 2" BSP |

1,1 |

2.4 |

S210A1101B |

|||

|

F 2" BSP-B Mouth*) |

1,1 |

2.4 |

S210A1101BI |

|||

|

F 1½" NPT |

— |

1,1 |

2.4 |

S208A1101 |

||

|

F 1½" NPT-B Mouth*) |

|

|

S208A1101I |

|||

|

F 2" NPT |

1,1 |

2.4 |

S211A1101 |

|||

|

F 2" NPT-B Mouth*) |

|

|

S211A1101I |

|||

|

F 1½" BSP |

Br |

PUR (Polyurethane) |

2,6 |

5.7 |

S207A2201B |

|

|

F 1½" BSP-B Mouth*) |

|

|

S207A2201BI |

|||

|

F 2" BSP |

2,4 |

5.3 |

S210A2201B |

|||

|

F 2" BSP-B Mouth*) |

|

|

S210A2201BI |

|||

|

F 1½" NPT |

— |

2,5 |

5.5 |

S208A2201 |

||

|

F 1½" NPT-B Mouth*) |

|

|

S208A2201I |

|||

|

F 2" NPT |

2,5 |

5.5 |

S211A2201 |

|||

|

F 2" NPT-B Mouth*) |

|

|

S211A2201I |

|||

|

F 1½" BSP |

SS |

PTFE (Teflon®) |

2,5 |

5.5 |

S207A4401A |

|

|

F 2" BSP |

2,3 |

5.1 |

S210A4401A |

|||

|

F 1½" NPT |

— |

2,4 |

5.3 |

S208A4401 |

||

|

F 2" NPT |

2,3 |

5.1 |

S211A4401 |

|||

|

F 1½" BSP |

Titan |

PTFE (Teflon®) |

1,3 |

2.9 |

S207A6601A |

|

|

F 2" BSP |

1,3 |

2.9 |

S210A6601A |

|||

|

F 1½" NPT |

— |

|

|

S208A6601 |

||

|

F 2" NPT |

1,4 |

3.1 |

S211A6601 |

|||

|

F 1½" BSP |

Hastelloy |

PTFE (Teflon®) |

2,3 |

5.1 |

S207A7701A |

|

|

F 2" BSP |

2,3 |

5.1 |

S210A7701A |

|||

|

F 1½" NPT |

— |

2,3 |

5.1 |

S208A7701 |

||

|

F 2" NPT |

2,3 |

5.1 |

S211A7701 |

|||

|

F 1½" BSP |

PEEK |

PTFE (Teflon®) |

|

|

S207A9901A |

|

|

F 2" BSP |

1,3 |

2.9 |

S210A9901A |

|||

|

F 1½" NPT |

— |

|

|

S208A9901 |

||

|

F 2" NPT |

1,3 |

2.9 |

S211A9901 |

|||

*) Geschikt voor oudere modellen Emco Wheaton mannelijke koppelingen

1) F = Binnendraad, BSP =

EN ISO 228, NPT = ANSI B1.20.1

2) Materiaal: Al = Aluminium, Br = Messing, SS = Roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijvoorbeeld EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

2" BSP AG |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

|

|

S278A1101 |

|

2" NPT AG |

|

|

S279A1101 |

||

|

S60 x 6 AG |

|

|

S2109A1101 |

||

|

W2" - 7 AG |

1,3 |

2.1 |

S2123A1101 |

||

|

2" BSP AG |

Br |

|

|

S278A2201 |

|

|

2" NPT AG |

|

|

S279A2201 |

||

|

S60x6 AG |

|

|

S2109A2201 |

||

|

W2" - 7 AG |

|

|

S2123A2201 |

||

|

2" BSP AG |

SS |

2,3 |

5.1 |

S278A4401 |

|

|

2" NPT AG |

|

|

S279A4401 |

||

|

S60x6 AG |

|

|

S2109A4401 |

||

1) M = Buitendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1, S 60 x 6 = schroefdraad voor IBC, W 2" stookolieaansluiting Zweden

2) Materiaal: Al = Aluminium, Br = Messing, SS = Roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijv. EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® en Teflon® zijn geregistreerde handelsmerken van DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 165 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

|

|

S219A1101 |

|

DN 40 PN 10 / 16 Type A |

|

|

S227A1101 |

||

|

1½" ASA 150 |

|

|

S255A1101 |

||

|

DN 50 PN 10 / 16 Type A |

2,3 |

5.1 |

S230A1101 |

||

|

2" ASA 150 |

|

|

S257A1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S265A1101 |

||

|

undrilled Ø 165 mm |

GM |

|

|

S219A2201 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

S227A2201 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A2201 |

||

|

1½" ASA 150 |

5,1 |

11.2 |

S255A2201 |

||

|

1½" ASA 300 |

|

|

S256A2201 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

S230A2201 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

S231A2201 |

||

|

2" ASA 150 |

5,1 |

11.2 |

S257A2201 |

||

|

2" ASA 300 |

|

|

S258A2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S265A2201 |

||

|

undrilled Ø 165 mm |

SS |

|

|

S219A4401 |

|

|

o. Bohrungen Ø 165 mm **) |

|

|

S219A4401F |

||

|

DN 40 PN 10 / 16 Type B |

|

|

S227A4401 |

||

|

DN 40 PN 10 / 16 Type B **) |

|

|

S227A4401F |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A4401 |

||

|

DN 40 PN 25 / 40 Type B **) |

|

|

S228A4401F |

||

|

1½" ASA 150 |

|

|

S255A4401 |

||

|

1½" ASA 150 **) |

|

|

S255A4401F |

||

|

1½" ASA 300 |

|

|

S256A4401 |

||

|

1½" ASA 300 **) |

6,6 |

14.6 |

S256A4401F |

||

|

DN 50 PN 25 / 40 Type E *) |

|

|

S229A4401 |

||

|

DN 50 PN 10 / 16 Type B |

5,4 |

11.9 |

S230A4401 |

||

|

DN 50 PN 10 / 16 Type B **) |

|

|

S230A4401F |

||

|

DN 50 PN 25 / 40 Type B |

5,4 |

11.9 |

S231A4401 |

||

|

DN 50 PN 25 / 40 Type B **) |

|

|

S231A4401F |

||

|

2" ASA 150 |

5,1 |

11.2 |

S257A4401 |

||

|

2" ASA 150 **) |

5,1 |

11.2 |

S257A4401F |

||

|

2" ASA 300 |

|

|

S258A4401 |

||

|

2" ASA 300 **) |

2,5 |

5.5 |

S258A4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S265A4401 |

||

|

DN 50 DIN 11864 |

3,1 |

6.8 |

S2152B4401 |

||

|

undrilled Ø 165 mm |

Titan |

|

|

S219A6601 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

S227A6601 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A6601 |

||

|

1½" ASA 150 |

|

|

S255A6601 |

||

|

1½" ASA 300 |

|

|

S256A6601 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

S230A6601 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

S231A6601 |

||

|

2" ASA 150 |

|

|

S257A6601 |

||

|

2" ASA 300 |

|

|

S258A6601 |

||

|

undrilled Ø 165 mm |

Hastelloy |

|

|

S219A7701 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

S227A7701 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A7701 |

||

|

1½" ASA 150 |

|

|

S255A7701 |

||

|

1½" ASA 300 |

|

|

S256A7701 |

||

|

DN 50 PN 10 / 16 Type B |

5,4 |

11.9 |

S230A7701 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

S231A7701 |

||

|

2" ASA 150 |

|

|

S257A7701 |

||

|

2" ASA 300 |

|

|

S258A7701 |

||

|

undrilled Ø 165 mm |

PEEK |

|

|

S219A9901 |

|

|

DN 40 PN 10 / 16 Type B |

5,4 |

11.9 |

S227A9901 |

||

|

1½" ASA 150 Type B |

|

|

S255A9901 |

||

|

DN 50 PN 10 / 16 Type B |

5,4 |

11.9 |

S230A9901 |

||

|

2" ASA 150 |

|

|

S257A9901 |

||

*) Type E (met spie),

EN 1092-1, zie pagina 44

**) Flens met standaarddikte

1) PN 10 / 16 / 25 / 40 = EN 1092

(typen zie pagina 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = oude standaard TW, 10 bar. DIN 11864 = DIN 11864-2 (aseptische flens).

2) Materiaal: Al = aluminium,

GM = brons, SS = roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijv. EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® is een geregistreerd handelsmerk van DuPont, DuPont Elastomers.

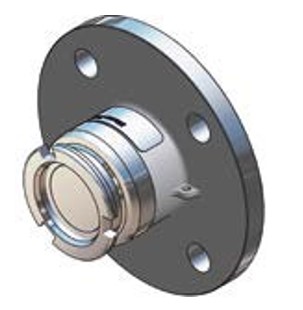

Tankeenheid (adapter) en slangeenheid (koppeling)

Volgens NAVO STANAG 3756

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

10 bar / 145 psi |

15 bar / 218 psi |

50 bar / 726 psi |

|

Brass / Gunmetal |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Stainless Steel |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Titan |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Hastelloy |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

PEEK |

6 bar / 87 psi |

9 bar / 131 psi |

30 bar / 435 psi |

Aansluitingen

2½" en 3" in BSP, NPT en geflensde inlaat.

Toepassingen

Voor het laden/lossen van tankwagens en spoorwagons, tanks en containers, of voor elke toepassing waarbij productverontreiniging en morsen tot een minimum moeten worden beperkt.

Media

Aardolieproducten: benzine, diesel, olie, enz. Chemische producten: ethyleenoxide, propyleenoxide, acrylonitril, butadieen, ammoniak, vinylchloride, tolueen, xyleen, zwavelzuur, fenol, enz.

Gas: dampterugwinnings-/balanssystemen voor diverse media.

Droog poeder

Materiaal behuizing

Aluminium, messing/brons, roestvrij staal, Hastelloy en PEEK. Andere materialen op aanvraag.

Afdichtingen

Standaardafdichtingen in FPM (Viton®), EPDM, Chemraz®, Kalrez®, NBR. Andere materialen op aanvraag.

Hoge stroomsnelheden / lage drukval

Maakt maximale productoverdracht mogelijk met minimale verliezen.

Aanbevolen maximale stroomsnelheden

1500 liter/minuut (brandstof)

Selectiviteit

- voorkomt productvermenging

Om productverontreiniging door het aansluiten van een slangunit op de verkeerde tankunit te voorkomen, zijn er verschillende uitvoeringen van de slang- en tankunits beschikbaar. Elke unit heeft een aantal selectieve posities, aangegeven met een gecodeerd onderdeelnummer volgens de koppelingsmaat - geef dit aan bij het plaatsen van de bestelling. Zie pagina 32 en verder.

Uitwisselbaarheid

Compatibel met koppelingen van andere fabrikanten.

Slangunit met geïntegreerde wartel

Alle slangunits worden geleverd met een geïntegreerde wartel.

Volgens NAVO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 2½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

1,0 |

2.2 |

T312D1101B |

|

F 3" BSP |

1,0 |

2.2 |

T314D1101B |

|||

|

F 2½" NPT |

— |

1,0 |

2.2 |

T313D1101 |

||

|

F 3" NPT |

1,1 |

2.4 |

T315D1101 |

|||

|

F 2½" BSP |

GM |

PUR (Polyurethane) |

2,7 |

6.0 |

T312D2201B |

|

|

F 3" BSP |

2,9 |

6.4 |

T314D2201B |

|||

|

F 2½" NPT |

— |

2,9 |

6.4 |

T313D2201 |

||

|

F 3" NPT |

3,2 |

7.1 |

T315D2201 |

|||

|

F 2½" BSP |

SS |

PTFE (Teflon®) |

2,5 |

5.5 |

T312B4401A |

|

|

F 3" BSP |

3,1 |

6.8 |

T314B4401A |

|||

|

F 2½" NPT |

— |

2,7 |

6.0 |

T313B4401 |

||

|

F 3" NPT |

3,7 |

8.2 |

T315B4401 |

|||

|

F 2½" BSP |

Hastelloy |

PTFE (Teflon®) |

2,6 |

5.7 |

T312A7701A |

|

|

F 3" BSP |

|

|

T314A7701A |

|||

|

F 2½" NPT |

— |

|

|

T313A7701 |

||

|

F 3" NPT |

|

|

T315A7701 |

|||

|

F 2½" BSP |

PEEK |

PTFE (Teflon®) |

|

|

T312A9901A |

|

|

F 3" BSP |

|

|

T314A9901A |

|||

|

F 2½" NPT |

— |

|

|

T313A9901 |

||

|

F 3" NPT |

|

|

T315A9901 |

|||

1) F = Binnendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Materiaal: Al = Aluminium, GM = Brons, SS = Roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijvoorbeeld EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® en Teflon® zijn geregistreerde handelsmerken van DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

2½" BSP |

|

|

1,0 |

2.2 |

T380A1101 |

|

|

3" BSP |

Al |

|

|

|

T382A1101 |

|

|

2½" NPT |

|

|

T381A1101 |

|||

|

3" NPT |

|

Standard: |

|

|

T383A1101 |

|

|

2½" BSP |

|

|

|

T380A2201 |

||

|

|

FPM/FKM |

|||||

|

3" BSP |

|

|

T382A2201 |

|||

|

GM |

(Viton®)

Other on |

|||||

|

2½" NPT |

|

|

T381A2201 |

|||

|

3" NPT |

|

|

T383A2201 |

|||

|

|

request. |

|||||

|

2½" BSP |

|

|

|

T380A4401 |

||

|

3" BSP |

SS |

|

|

|

T382A4401 |

|

|

2½" NPT |

|

|

T381A4401 |

|||

|

3" NPT |

|

|

|

|

T383A4401 |

|

1) M = Male thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 210 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

2,1 |

4.6 |

T320D1101 |

|

DN 65 PN 10 / 16 Type A |

1,6 |

3.5 |

T333D1101 |

||

|

DN 80 PN 10 / 16 Type A |

1,8 |

4.0 |

T336D1101 |

||

|

2½" ASA 150 |

1,7 |

3.8 |

T359D1101 |

||

|

3" ASA 150 |

1,8 |

4.0 |

T361D1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

1,3 |

2.9 |

T365D1101 |

||

|

DIN 28459 'TW 3' / DN 100 |

1,7 |

3.8 |

T366D1101 |

||

|

3" TTMA |

1,4 |

3.1 |

T367D1101 |

||

|

4" TTMA |

1,5 |

3.3 |

T368D1101 |

||

|

undrilled Ø 210 mm |

GM |

6,2 |

13.7 |

T320D2201 |

|

|

DN 65 PN 10 / 16 Type B |

4,9 |

10.8 |

T333D2201 |

||

|

DN 65 PN 25 / 40 Type B |

|

|

T334D2201 |

||

|

DN 80 PN 10 / 16 Type B |

|

|

T336D2201 |

||

|

DN 80 PN 25 / 40 Type B |

|

|

T337D2201 |

||

|

2½" ASA 150 |

4,4 |

9.7 |

T359D2201 |

||

|

2½" ASA 300 |

|

|

T360D2201 |

||

|

3" ASA 150 |

4,4 |

9.7 |

T361D2201 |

||

|

3" ASA 300 |

|

|

T362D2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

4,4 |

9.7 |

T365D2201 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

T366D2201 |

||

|

3" TTMA |

|

|

T367D2201 |

||

|

4" TTMA |

4,2 |

9.3 |

T368D2201 |

||

|

undrilled Ø 210 mm |

SS |

|

|

T320B4401 |

|

|

o. Bohrungen Ø 210 mm **) |

|

|

T320B4401F |

||

|

DN 65 PN 25 / 40 Type E *) |

|

|

T332B4401 |

||

|

DN 65 PN 10 / 16 Type B ) |

4,2 |

9.3 |

T333B4401 |

||

|

DN 65 PN 10 / 16 Type B ** |

|

|

T333B4401F |

||

|

DN 65 PN 25 / 40 Type B ) |

4,3 |

9.5 |

T334B4401 |

||

|

DN 65 PN 25 / 40 Type B ** |

4,3 |

9.5 |

T334B4401F |

||

|

DN 80 PN 10 / 16 Type E *) |

|

|

T335B4401 |

||

|

DN 80 PN 10 / 16 Type B ) |

4,7 |

10.4 |

T336B4401 |

||

|

DN 80 PN 10 / 16 Type B ** |

|

|

T336B4401F |

||

|

DN 80 PN 25 / 40 Type B ) |

|

|

T337B4401 |

||

|

DN 80 PN 25 / 40 Type B ** |

|

|

T337B4401F |

||

|

2½" ASA 150 ) |

4,0 |

8.8 |

T359B4401 |

||

|

2½" ASA 150 ** |

|

|

T359B4401F |

||

|

2½" ASA 300 ) |

4,5 |

9.9 |

T360B4401 |

||

|

2½" ASA 300 ** |

4,5 |

9.9 |

T360B4401F |

||

|

3" ASA 150 ) |

4,5 |

9.9 |

T361B4401 |

||

|

3" ASA 150 ** |

|

|

T361B4401F |

||

|

3" ASA 300 ) |

|

|

T362B4401 |

||

|

3" ASA 300 ** |

|

|

T362B4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

T365B4401 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

T366B4401 |

||

|

3" TTMA |

|

|

T367B4401 |

||

|

4" TTMA |

|

|

T368B4401 |

||

*) Type E (with spigot),

EN 1092-1, see page 44

**) Flange with standard thickness

1) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. TTMA = Standard of the Truck Trailer Manufacturers Association

2) Material: Al = Aluminium,

GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® is a registred trademark of DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

Normec (120 x 120 mm) |

Al |

Standard: FPM/FKM (Viton®) |

|

|

T3107D1101 |

|

Normec (120 x 120 mm) |

GM |

|

|

T3107D2201 |

|

1) Normec = with drilling for Italian road tanker connection

2) Material: Al = Aluminium, GM = Gunmetal

3) Standarddichtung FPM/FKM. Alternative Materialien,

Volgens NAVO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 2½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethan) |

3,3 |

7.3 |

S312B1101B |

|

F 3" BSP |

3,6 |

7.9 |

S314B1101B |

|||

|

F 2½" NPT |

— |

3,4 |

7.5 |

S313B1101 |

||

|

F 3" NPT |

3,5 |

7.7 |

S315B1101 |

|||

|

F 2½" BSP |

GM |

PUR (Polyurethan) |

7,3 |

16.1 |

S312B2201B |

|

|

F 3" BSP |

7,4 |

16.3 |

S314B2201B |

|||

|

F 2½" NPT |

— |

|

|

S313B2201 |

||

|

F 3" NPT |

7,6 |

16.8 |

S315B2201 |

|||

|

F 2½" BSP |

SS |

PTFE |

6,7 |

14.8 |

S312B4401A |

|

|

F 3" BSP |

6,6 |

14.6 |

S314B4401A |

|||

|

F 2½" NPT |

— |

6,6 |

14.6 |

S313B4401 |

||

|

F 3" NPT |

6,6 |

14.6 |

S315B4401 |

|||

|

F 2½" BSP |

Hastelloy |

PTFE |

6,8 |

15.0 |

S312A7701A |

|

|

F 3" BSP |

|

|

S314A7701A |

|||

|

F 2½" NPT |

— |

|

|

S313A7701 |

||

|

F 3" NPT |

|

|

S315A7701 |

|||

|

F 2½" BSP |

PEEK |

PTFE |

|

|

S312A9901A |

|

|

F 3" BSP |

|

|

S314A9901A |

|||

|

F 2½" NPT |

— |

|

|

S313A9901 |

||

|

F 3" NPT |

|

|

S315A9901 |

|||

Volgens NAVO STANAG 3756

|

Flange 1B) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 210 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

|

|

S320B1101 |

|

DN 65 PN 10 / 16 Type A |

10,0 |

22.1 |

S333B1101 |

||

|

DN 80 PN 10 / 16 Type A |

|

|

S336B1101 |

||

|

2" ASA 150 |

|

|

S357B1101 |

||

|

2½" ASA 150 |

|

|

S359B1101 |

||

|

3" ASA 150 |

|

|

S361B1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S365B1101 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S366B1101 |

||

|

3" TTMA |

|

|

S367B1101 |

||

|

4" TTMA |

|

|

S368B1101 |

||

|

undrilled Ø 210 mm |

GM |

|

|

S320B2201 |

|

|

DN 65 PN 10 / 16 Type B |

|

|

S333B2201 |

||

|

DN 65 PN 25 / 40 Type B |

|

|

S334B2201 |

||

|

DN 80 PN 10 / 16 Type B |

|

|

S336B2201 |

||

|

DN 80 PN 25 / 40 Type B |

|

|

S337B2201 |

||

|

2" ASA 150 |

|

|

S357B2201 |

||

|

2½" ASA 150 |

|

|

S359B2201 |

||

|

2½" ASA 300 |

|

|

S360B2201 |

||

|

3" ASA 150 |

|

|

S361B2201 |

||

|

3" ASA 300 |

|

|

S362B2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S365B2201 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S366B2201 |

||

|

3" TTMA |

|

|

S367B2201 |

||

|

4" TTMA |

|

|

S368B2201 |

||

|

undrilled Ø 210 mm |

SS |

|

|

S320B4401 |

|

|

undrilled Ø 210 mm**) |

|

|

S320B4401F |

||

|

DN 65 PN 25 / 40 Type E*) |

|

|

S332B4401 |

||

|

DN 65 PN 10 / 16 Type B |

10,0 |

22.1 |

S333B4401 |

||

|

DN 65 PN 10 / 16 Type B**) |

|

|

S333B4401F |

||

|

DN 65 PN 25 / 40 Type B |

|

|

S334B4401 |

||

|

DN 65 PN 25 / 40 Type B**) |

|

|

S334B4401F |

||

|

DN 80 PN 10 / 16 Type E*) |

|

|

S335B4401 |

||

|

DN 80 PN 10 / 16 Type B ) |

|

|

S336B4401 |

||

|

DN 80 PN 10 / 16 Type B** |

|

|

S336B4401F |

||

|

DN 80 PN 25 / 40 Type B |

|

|

S337B4401 |

||

|

DN 80 PN 25 / 40 Type B**) |

|

|

S337B4401F |

||

|

2" ASA 150 ) |

|

|

S357B4401 |

||

|

2" ASA 150** |

|

|

S357B4401F |

||

|

2½" ASA 150 ) |

6,6 |

14.6 |

S359B4401 |

||

|

2½" ASA 150** |

6,6 |

14.6 |

S359B4401F |

||

|

2½" ASA 300 |

|

|

S360B4401 |

||

|

2½" ASA 300**) |

|

|

S360B4401F |

||

|

3" ASA 150 |

|

|

S361B4401 |

||

|

3" ASA 150**) |

|

|

S361B4401F |

||

|

3" ASA 300 |

|

|

S362B4401 |

||

|

3" ASA 300**) |

|

|

S362B4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S365B4401 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S366B4401 |

||

|

3" TTMA |

|

|

S367B4401 |

||

|

4" TTMA |

|

|

S368B4401 |

||

*) Type E (met spie),

EN 1092-1, zie pagina 44

**) Flens met standaarddikte

1A) F = Binnendraad, BSP = EN ISO 228, NPT = ANSI B1.20.1

1B) PN 10 / 16 / 25 / 40 = EN 1092

(typen zie pagina 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = oude standaard TW, 10 bar. TTMA = Truck Trailer Manufacturers Association

2) Materiaal: Al = Aluminium, GM = Brons, SS = Roestvrij staal

3) Standaard afdichting FPM/FKM. Alternatieve materialen, bijv. EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag

Viton® en Teflon® zijn geregistreerde handelsmerken van DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

DIN 28459 'TW 1' / DN 80 |

|

Standard: |

1,6 |

3.5 |

T465I1101 |

|

|

DIN 28459 'TW 3' / DN 100 |

|

1,6 |

3.5 |

T466I1101 |

||

|

FPM/FKM |

||||||

|

Al |

(Viton®) |

|||||

|

3" TTMA |

|

|

T467I1101 |

|||

|

|

Other on |

|||||

|

|

request. |

|||||

|

4" TTMA |

|

|

T468I1101 |

|||

De 15° verlaagde tankunit met flensaansluiting vergemakkelijkt de aansluiting bij hoge plaatsing en vermindert slangslijtage.

1) DIN 28459 = oude standaard TW, 10 bar. TTMA = Truck Trailer Manufacturers Association

2) Materiaal: Al = aluminium

3) Standaard afdichting FPM/FKM. Alternatieve materialen, zoals EPDM, Chemraz®, Kalrez®, NBR of HNBR op aanvraag.

Viton® is een geregistreerd handelsmerk van DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

Normec (120x120 mm) |

Al |

Standard: FPM/FKM (Viton®) |

|

|

T4107D1101 |

|

Normec (120x120 mm) |

GM |

|

|

T4107D2201 |

|

1) Normec = with drilling for Italian road tanker connection

2) Material: Al = Aluminium, GM = Gunmetal

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® is a registred trademark of DuPont, DuPont Elastomers.

Volgens NAVO STANAG 3756

Niet de juiste Dry Disconnect Couplings gevonden?

Vul onderstaand formulier in en wij helpen u verder!

Benieuwd naar onze blog? Bekijk hier al onze items!

Lees meer